- Different types of patterns:

the types of pattern used depends upon the design of casting, complexity of shape, the number of casting required moulding process, surface finish and accuracy.

The common types of patterns are:

1) Single piece pattern

2) Split piece pattern

3) Loose piece pattern

4) Gated pattern

5) Match pattern

6) Sweep pattern

7) Cope and drag pattern

8) Skeleton pattern

9) Shell pattern

10) Follow board pattern

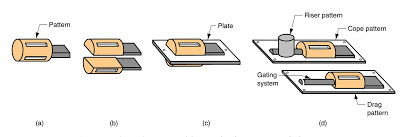

Figure 1: Single piece, Split, Match-plate, Cope and Drag Pattern

- Single piece pattern:

This is the simplest type of pattern, exactly like the desired casting. For making a mould, the pattern is accommodated either in cope or drag.

Used for producing a few large castings, for example, stuffing box of steam engine.

- Split pattern:

These patterns are split along the parting plane (which may be flat or irregular surface) to facilitate the extraction of the patternout of the mould before the pouring operation. For a more complex casting, the pattern may be split in more than two parts.

- Loose piece pattern:

When a one piece solid pattern has projections or back drafts which lie above or below the parting plane, it is impossible to with drawit from the mould. With such patterns, the projections are made with the help of loose pieces. One drawback of loose feces is that their shifting is possible during ramming.

Figure: Loose piece pattern

- Gated pattern:

A gated pattern is simply one or more loose patterns having attached gates and runners.Because of their higher cost, these patterns are used for producing small castings in mass production systems and on molding machines.

Figure: Gated pattern

- Match plate pattern:

A match plate pattern is a split pattern having the cope and drags portions mounted on opposite sides of a plate (usually metallic), called the "match plate" that conforms to the contour of the parting surface.

The gates and runners are also mounted on the match plate, so that very little hand work is required. This results in higher productivity. This type of pattern is used for a large number of castings.

Piston rings of I.C. engines are produced by this process.

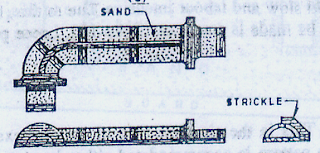

- Sweep pattern:

A sweep is a section or board (wooden) of proper contour that is rotated about one edge to shape mould cavities having shapes of rotational symmetry. This type of pattern is used when a casting of large size is to be produced in a short time. Large kettles of C.I. are made by sweep patterns.

Figure: Sweep pattern

- Cope and drag pattern:

A cope and drag pattern is a split pattern having thecope and drag portions each mounted on separate match plates. These patterns are used when in the production of large castings; the complete moulds are too heavy and unwieldy to be handled by a single worker.

- Skeleton pattern:

For large castings having simple geometrical shapes, skeleton patterns are used. Just like sweep patterns, these are simple wooden frames that outline the shape of the part to be cast and are also used as guides by the molder in the hand shaping of the mould.

This type of pattern is also used in pit or floor molding process.

Figure: Skeleton pattern

- Shell pattern:

Figure: Shell pattern

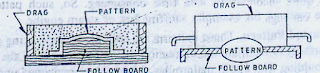

- Follow board pattern:

A follow board is not a pattern but is a device (wooden board) used for various purposes.

Figure : Follow board pattern

Comments

Post a Comment